NanoCutting includes a group of similar processes:

- Nano-imprints to press a user exchangeable tip into a sample: once, by acceleration, in arrays, or by bitmap patterns.

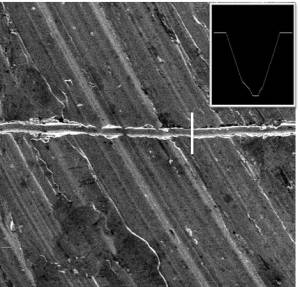

- Nano-lines or arrays of lines to cut a field out of the sample, e.g. with a diamond tip

- Nano-slicing of samples fixed on top of a substrate, e.g. wool fibers, bio-structures etc.: with a sharp knife by friction.

- Freely programmable loops, macros and combinations out of these processes.

The features of the Nanoworkbench enable:

- Live Image Positioning e.g. to select the imprint points or the lines to cut

- Nanofinger® Scouting for guiding the cutter to a flat sample or with the 3D-Nanofinger® package to measure a height profile on a rough sample and guide the cutter parallel to that topography.

- The Sequencer can embed pre-defined cutting macros into complete processes.

- customized cutters in various shapes and materials are available

- up to 1000 times faster milling than by FIB systems

- 1 nm movement resolution on 20 x 20 x 10 mm3 cutting stroke

- automatic macros that can be freely edited by the user

- NanoCutting is an application package of the Nanoworkbench

- NanoCutting can be combined with the 3D-Nanofinger® application package to cut along a measured topography.

- NanoCutting can be combined with the application package NanoCleaning, to clean the cutter tip in-between, in-situ, in automation, incredible.

This application package is part of the Nanoworkbench

Cutting an array of lines

Slicing through a cloth fiber