With the Nanoworkbench from Klocke Nanotechnik abrasive wear tests are very fast, easy and secure:

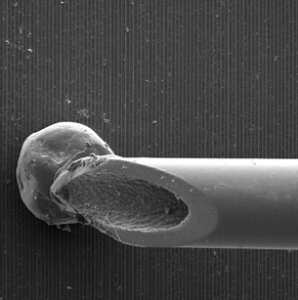

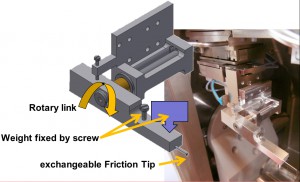

- Any tool can be fixed at the wear tester head to rub over a sample, in-situ visible in the SEM image.

- A weight can be fixed at the arm of the tool holder to add a defined pressure onto the friction tool.

- The friction tool is navigated by Live Image Positioning in xy and by the 1D-Nanofinger® (operating as Scout) in z onto the sample, just by mouse-click, also onto isolators.

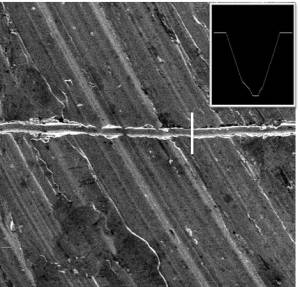

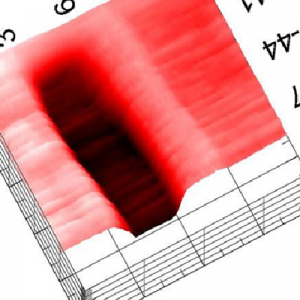

- An automatic macro moves the friction tool along a line (defined by Live Image Positioning), several times scratching along the surface. After a set of such lines the 2D-Nanofinger® (operating in Linescan mode) measures by a Linescan perpendicular to the scratch the depth of the scratched line.

- Repeating this macro in an outer loop shows the digging into the sample, Linescan by Linescan.

- Since all macros of the Nanoworkbench can be edited many variations of this process can be designed by any user.

- exchangeable friction tool as front-end

- weight holder for exchangeable loads

- 1 nm movement resolution

- range of friction tool and 2D-Nanofinger® Linescan measurement: 20x20x10 mm3

- freely editable macros

- Nano Friction is an application package of the Nanoworkbench

- Besides the Nanoworkbench standard package it includes the wear tester module and a 2D-Nanofinger® Linescan module

This application package is part of the Nanoworkbench