- The Nanoworkbench from Klocke Nanotechnik enables the hand-eye coordination inside of SEM/FIB systems and opens the door to a complete new world of applications.

- Most handling, manipulation and measurement tasks done under light microscopes are now possible in any SEM/FIB: safe, easy and fast.

- Standard Application Packages are available including automation of the handling process and the SEM/FIB.

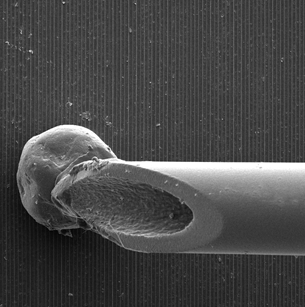

- Self Finding Tool: The 1D-Nanofinger® is used as “Scout” to detect sample and tool positions for automatic tool Approach.

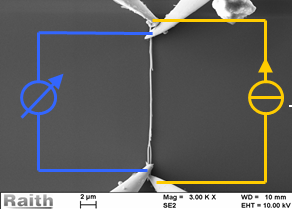

- Live Image Positioning: Click with the mouse into the SEM image, and the tool moves automatically to this position.

- Assistants (Wizards): One window guides the user through any process.

- Sequencer for automation: Any process can be programmed by simple teaching. The SEM/FIB features are included in our automation, e.g. setting of Zoom & Focus or sample stage movements. Even the Assistants can be programmed freely.

- Macro Executor: establishes a selectable list of macros that can include Assistants, Live Image Positioning and anything that was programmed previously with the Sequencer.

- Remote Control: The Macro Executor has access to the whole control system. So it is possible to have an external master program controlling the whole Nanorobotics world by this interface – including automation of the SEM.

- One “standard application package” out of a list – including a standard tool, a standard sample and a pre-defined process.

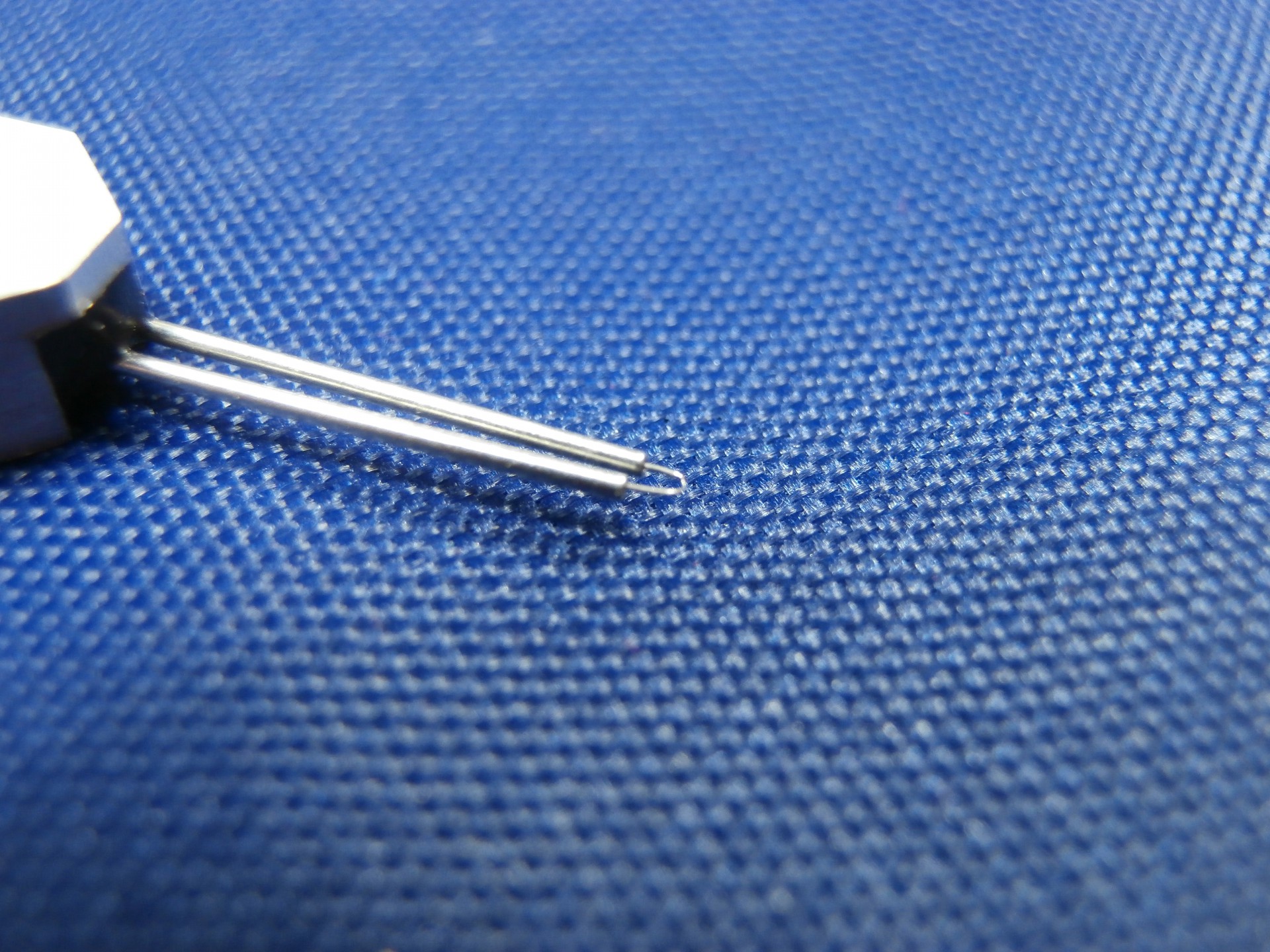

- The hardware of the Nanoworkbench, including 2 high-end Nanorobotics Manipulators, controllers and accessory.

- CAD construction and components for the in SEM/FIB system integration as turnkey solution.

- The “Nanoworkbench Standard Packet” including the basic application package “Nanomanipulation” with the 1D-Nanofinger® operating as Scout.

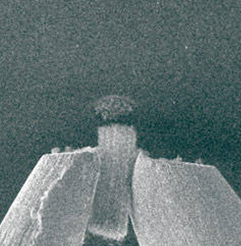

- Choose one additional “Application Package” out of: NanoCutting or NanoCleaning or NanoProbing or TEM-Lamella handling or 3D-Nanofinger or Force-Distance Measurement or Particle sorting or NanoFriction or Spot Heating – or out of further future application packages.

The Nanoworkbench

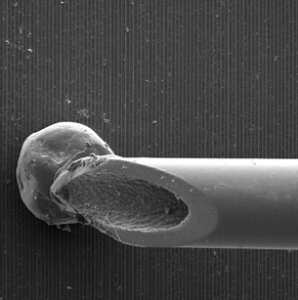

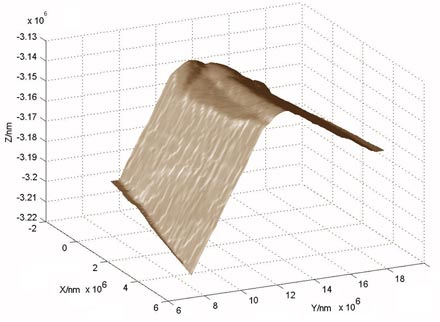

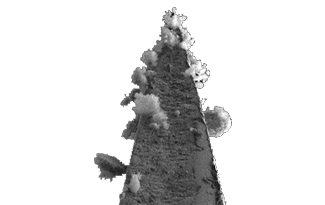

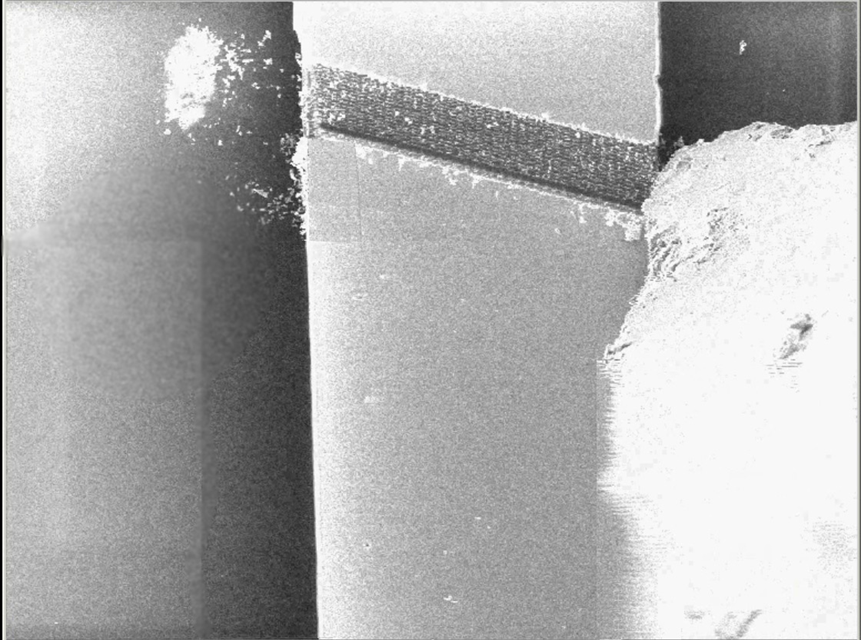

In light microscopy it is natural to use toolsets like tweezers, knives, probes and several different measurement tools. Without this many present-day products and methods would not exist. The operators of SEM/FIB-Systems generally work without toolsets, although the wavelength limit of light is no physical boundary. It can be imagined how technology would be pushed when a SEM/FIB Workbench reaches the same degree of practicability and utilization as toolsets for light microscopes. The Nanoworkbench is the first system substituting the eye-hand coordination effectively with nm precision in a SEM/FIB-system. The Nanoworkbench features a set of applications including TEM lamella preparation, nano probing, nano cutting, nano cleaning, force distance measurement, particle sorting and material preparation. Every application supports automated processes so almost no user interaction is needed. Even complex processes can be done within seconds and even by untrained users. Applications can be combined to create new and more complex processes. Expanding the SEM/FIB to a material processing system and a nano-analytical workbench by utilizing the Klocke Nanoworkbench enables new applications in research and production of material research, live sciences, tribology, environmental & forensic research and semiconductor technology.

Application packages of the Nanoworkbench

Nanoworkbench Award

we are proud to present our Microscopy Today 2015 Innovation Award for the development of the Klocke Nanotechnik Nanoworkbench