- NanoControl is one Software System from Klocke Nanotechnik that controls all Nanorobotics: from a single Nanomotor® over the Nanoworkbench up to complete Micro Production Systems – in one single release.

- The panels for a particular Nanorobotics system are automatically configured out of the Purchase Order Confirmation for a project by our ERP system.

- NanoControl includes a Manual Control Graphical User Interface and many Purchase Order related modules like a Sequencer for automation by simple teaching, a macro executor, assistants, a Live Image Positioning module, measurement diagrams, pattern recognition and plenty of I/O interfaces.

- A few of these modules are listed here.

- Design your own user interface with those commands your task needs.

- Directly control movements at the nanometer scale using mouse or keypad input.

- The flexible architecture allows for controlling many different hardware devices.

- Use complex functions like approaching a surface with the Nanofinger® with the click of one button, just like the most simple move commands.

- Traffic signs show the operation status of every device for an easy overview.

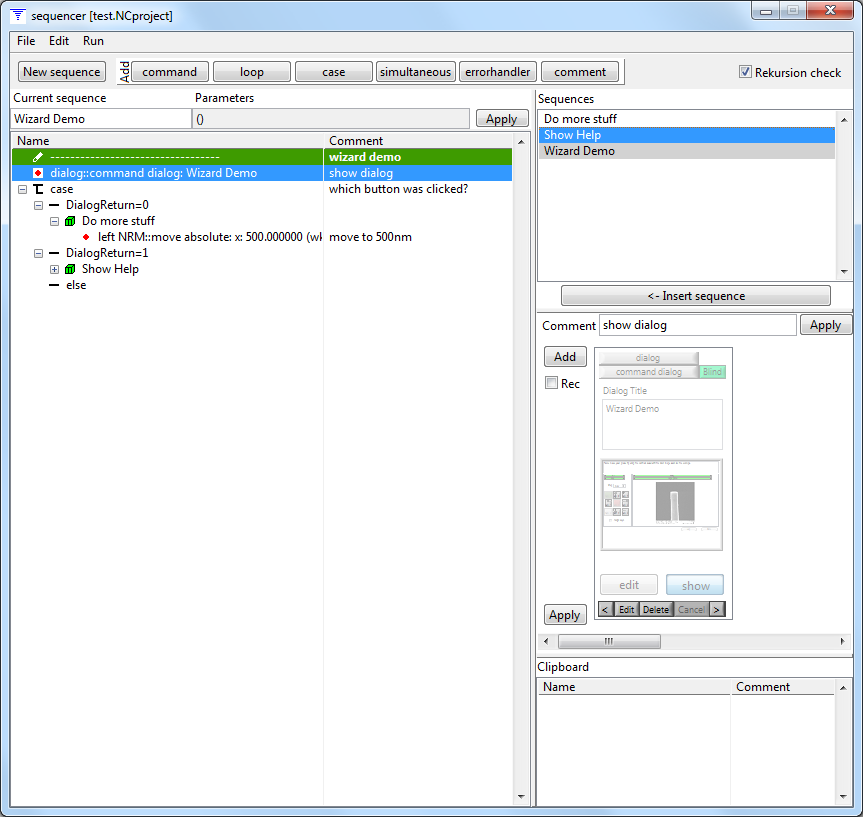

- Record commands from the manual control window into a sequence to be repeated later.

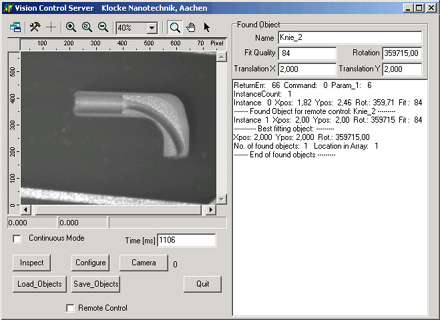

- Call the “Live Image Positioning” module or Pattern Recognition within your process to get coordinates for your processes.

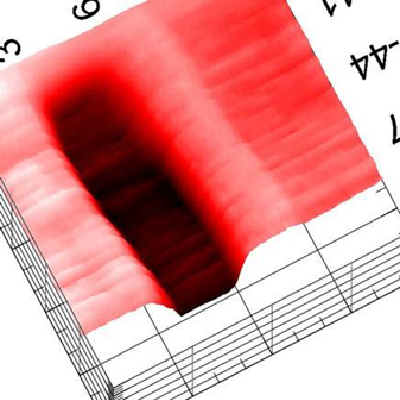

- Call diagram modules to record and show data sets during your process.

- Include “Assitant” steps for semi-automated processes with user interactions.

- Move the SEM/FIB stage, change Focus and Zoom automatically during your process.

- Easily modify, move or duplicate recorded commands.

- Use control structures like loops or conditions without need for programming knowledge.

- Modify all the predefined Nanoworkbench sequences to your specific Needs, also those of the Standard Application packages.

- Use the same sequencer from an easy few line macro up to a complex micro production process.

- Although the usage is so simple this Sequencer offers flexible programming in depth like a Compiler.

- Select a few Manual Control panels to be used in this “Assistant” command step,

- write an instruction text what to do with them,

- add any instructive Picture if needed,

- add a Done/Cancel/OK Button,

- move this Assistant window to a position on the Screen.

Now you have defined your Assistant step that can be used in Manual Control or called by the Sequencer(!).

- Navigate your Tools directly by dragging the cursor on the SEM or camera image.

- Mark one or several positions in the live image, for later positioning of Tools or the sample stage to these target points.

- Use a Vision system for Pattern Recognition of video camera images to automate your tasks

- Utilize up to 4 cameras from different angles

- Fully sequencer programmable

- Macros recorded by the Sequencer can be published in the “Macro Executor”, that seems to be just a menu list of macro entries.

- Select a macro name out of this list, and that macro runs. It may be just a move command or a complete process.

- In addition these macros can be called from outside of NanoControl by any other Software. In this moment NanoControl steps back: from the MASTER into the SLAVE mode. Anything taught with the Sequencer can so be called from outside, e.g. also SEM commands…

NanoControl

Our modular and highly flexible software package allows manual and automated control from a single Nanomotor up to a complete micro production system.

With a customizable user interface you have the controls you need for your specific task right at your fingertips. Our modular software can control a wide variety of devices including our Nanorobotics and many third-party devices like electron microscopes, stepper motors, power sources and GPIO cards. The control panels range from basic commands (e.g. move x nm) to complex procedures (e.g. automatically approach the surface with the Nanofinger) with a single button.

Develop your own wizard-driven applications by recording manually controlled movements into the sequencer or create complex programs directly, no programming skills required. The ability to control the SEM stage and imaging are especially useful to automate in situ processes.