The “Nanoflow” Dispenser system was developed by Klocke Nanotechnik for the usage within our Micro Production Systems, e.g. for the mass production of glass fiber assemblies in a precision that was not possible before. Nanoflow combines the properties of a simple and manually easy-to-use dispenser with the full automation capability of intelligent high-precision production line dispensers – at a favorable price.

- Highest precision: smallest drops can e.g. be generated directly at the output head

- Manual usage and within automation: processes can be developed by manual usage and later be repeated in complex automation systems.

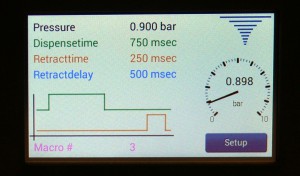

- Predictable results: by controlled parameters such as pressure, temperature and reservoir level

- Real-time pulse sequences and pressure changes generated directly in the device to avoid communication bottlenecks.

- Intelligent macros controlled by footswitch

-

Cartridge holder with angle adapter for horizontal dispensing without piston.

-

Cartridge holder with needle support against position errors caused by pressure changes.

-

Mini – dispensing head that requires no cartridge.

-

External fast, compact valve including back-suction.

-

Heating and cooling mini-dispensing head including temperature measurement.

-

Customized ultra-thin capillary tubes.